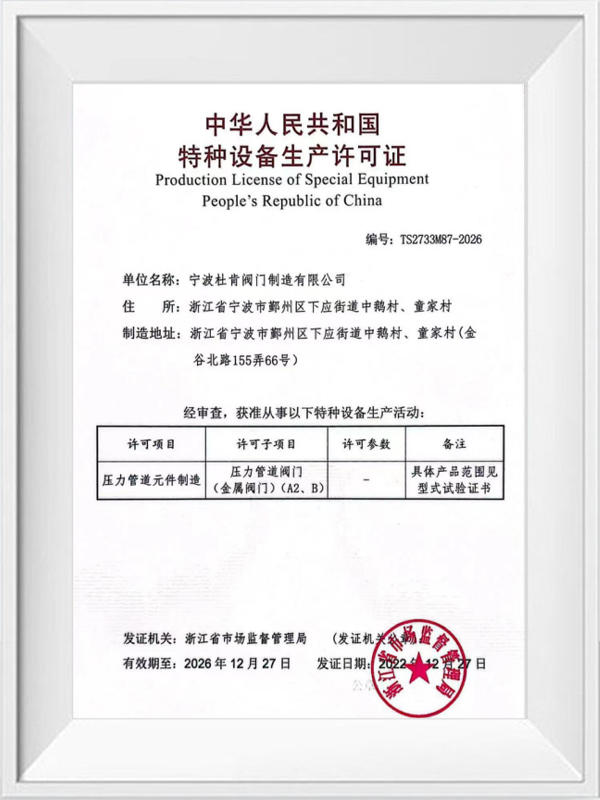

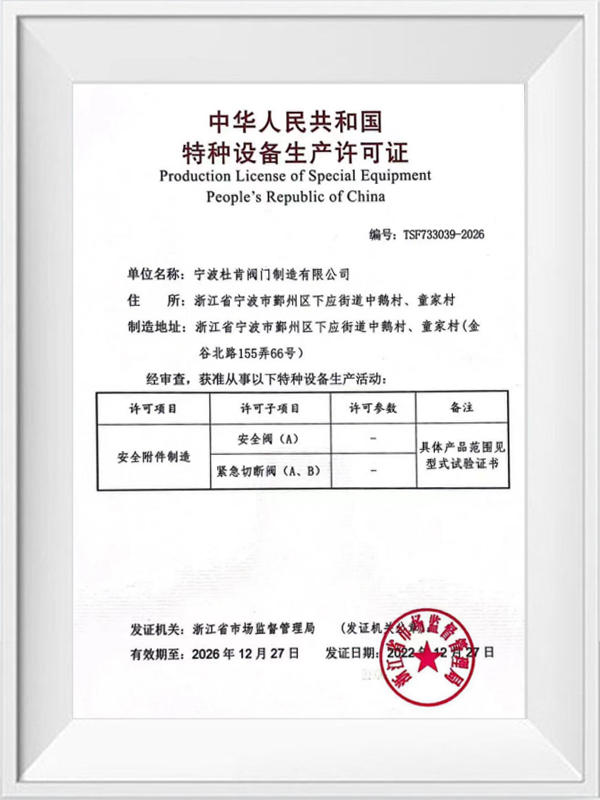

The company is headquartered in Ningbo, the economic center of Zhejiang Province, a modern international port city. Docan is a high-tech joint-stock company specializing in the design, manufacture, sales and related technical services of valves. The company has a registered capital of 50 million yuan and currently owns Valve TS manufacturing license issued by the General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China.

It has machining centers, CNC machine tools, CNC boring and milling machines, ordinary machine tools, and other sophisticated mechanical processing equipment and metal heat treatment equipment. It has various complete testing methods such as material chemical composition analysis, mechanical performance testing, and UT, MT, and PT non-destructive testing. Desktop spectrometer, material impact testing machine, portable hardness (Browi) testing machine, ultrasonic wall thickness meter ultra-low temperature testing system, torque testing system, low-temperature leakage testing system and other testing equipment can effectively control product quality.

At the beginning of the establishment of the company, it was established to develop the market with technological innovation and quality first. So that enterprises in the product technology leadership, advanced technology. Obtain customer satisfaction by pursuing high quality and full-process service. Bigger and stronger in scale. The company's products mainly include: ultra-low temperature full range of high and low pressure valves (globe valves, check valves, ball valves, emergency shut-off valves, safety valves, regulating valves), gate valves, ball valves, globe valves, butterfly valves, etc. "Quality, quality, brand" is our company's business goal, "doing practical things, focusing on practical results, sincere cooperation, and common development" is our code of conduct. We are willing to establish long-term and stable strategic partnerships with every customer to achieve mutual benefits. Winning is the consistent pursuit of our company.

English

English